I new here and somewhat new to the world of ROVs. Since I was in 5th grade I have always wanted to build one but never had the necessary means to do so. For a science project in that grade I made a small submersible out of medical containers glued together that worked with a forward and reverse pump complete with ballast tanks and counterweight. Now since I am a robotics engineering student at Worcester Polytechnic Institute I now have the necessary means to build the ROV that I have always wanted to.

The purpose of this project is to force myself to improve my skill set, build an actual robot from non kit parts, gain recognition on campus in preparation for my MQP next year, and of course fun.

In order to keep the project moving fast and without delays I am going the route of just using simple bilge pumps for moving in Cartesian space. I plan to use four 1100 gpf bilge pumps at each corner attached with custom brackets to a PVC frame that I have already built.

Instead of using a neutrally buoyant design like most ROVs I would like to increase the complexity of the project by using a ballast tank like system, I will have two tanks made out of 6 in diameter PVC pipe and endcaps, inside will be smaller bilge pumps mounted and connected to valves. There will be two valves per tank actuated by solenoids (gonna get water proof solenoid valve combos) this will allow me to fill the tanks with water and flush the air out when descending to lower depths. The valves will also aid in retaining air put back into the tanks when the water is being flushed out for surfacing. I intend to have a compressed air supply on board made from canned air cans connect to a brass fitting setup, this rig will be connected to the solenoid valves on the two ballast tanks and be used to fill the tanks with air as the bilge pup works in reverse emptying the water. I will need some sort of sensor configuration to keep track of the ballast tanks but I have not decide what that is going to entail yet.

As for electrical control and features I am going to use high current relays to control the bilge pumps from a tether connected to my custom designed robot controller development board. The board will take command from a PC over serial com port using a RS232 shifter to communicate with the AVR Atmega 644P maser controller on my dev-board. I plan to control everything from a Java dashboard on my PC/Mac, in the dashboard I will have an option of camera feeds to choose from or I may have the camera I am putting on the ROV move in multiple directions. All the electronics are going to be housed in a PVC electrical junction box that will be sealed with silicone, is this a safe idea?

my dev board with ground planes turned off:

Uploaded with ImageShack.us

TO handle the camera feed I will be using a Netduino Plus with a USB Host shield to send the data from a USB web cam over ethernet to the computer where it will be decoded by the java dashboard for viewing by the pilot. In order to do this I will be writing custom software in C# that will run on the netduino to handle the routing of the USB camera data over ethernet. The reason for this is to avoid having to make a custom cable with op amps every 16 to feet to avoid signal being degraded for the USB camera.

Netduino Plus:

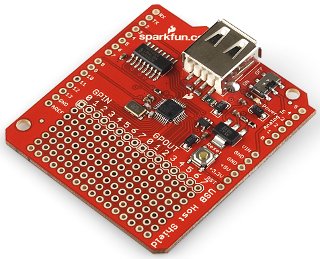

USB Host Shield:

This what I have in mind so far, in the future I am planning on adding a robotic arm with 3 degrees of freedom and a servo gripper, the arm will feature cameras on it to track where it is as well as encoders on each joint's actuator but that is long down the road when i get better with inverse kinematics. The initial goal here is to build the platform and get it working and get the vision system working.

Here is the frame I have build:

Uploaded with ImageShack.us

I am debating where or not reducing the height of the frame, its up in the air but I did not glue it together yet so its not finalized and open for change.

I still need to design brackets that will attach to the pipe at each corner to mount each pump, I am waiting until I get ther pumps so that I can get realistic dimensions off them before I design and manufacture the parts. Does anyone here recommend a material that is both strong and light as well as having the ability to be cut on a laser cutter?

More to come I welcome any and all criticism and suggestions!